|

|

|

|

|

|

Home |

Client List |

Careers |

Contact Us |

Site Map |

| About Us | Machines | Plants & Projects | Services | Why Us? | News | More Links |

:: OUR PRODUCTS ::

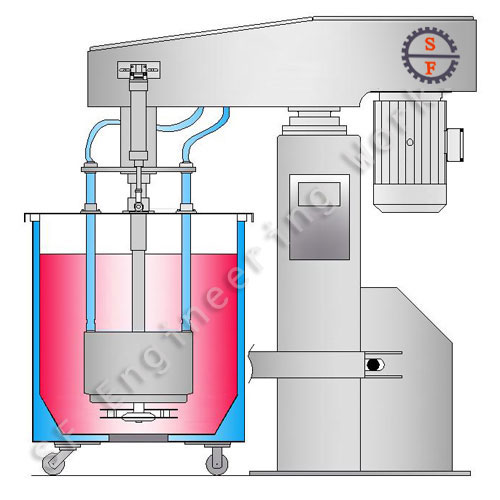

Dispersing and Milling / Basket Mill

|

BASKET MILL:Complete mixing and dispersing in a single tank.

The Basket Mill is an exceptionally versatile dispersion system that can be applied to a wide range of processing industries. Offering the very highest degree of efficiency and dependability, the ring mill is specifically engineered to allow complete mixing and dispersing in a single tank. From dry pigment addition to dispersion to let- down ... all can be fully accomplished without tank or blade changes, without time-consuming clean-ups and without operator interaction. Now high efficiency is simplicity itself. The Basket Mill has redefined batch dispersion systems. This design insures that your materials pass through the high-density dispersion zone within the milling chamber at a high frequency. This system offers a high degree of dispersion, which can be many times more efficiency, is achieved without pipes, pumps or material transfer. The simplicity of the Mill system allows for very high material yields from batch to batch, as high as 99%. This means less clean-up and a reduction in waste solvents. Premixing, dispersion, compounding and dilution are all accomplished in a single unit that requires less space, less time and less energy to achieve bigger results. |

|||||||||||||||||||||||||||||||||

ADVANTAGES:

OPTIONAL: Twin Shaft Basket Mill

Note: HP of motor may increase / decrease depending on product. Single Shaft Basket Mill

| ||||||||||||||||||||||||||||||||||