|

|

|

|

|

|

Home |

Client List |

Careers |

Contact Us |

Site Map |

| About Us | Machines | Plants & Projects | Services | Why Us? | News | More Links |

:: OUR PRODUCTS ::

Dispersing and Milling / Bead Mill

|

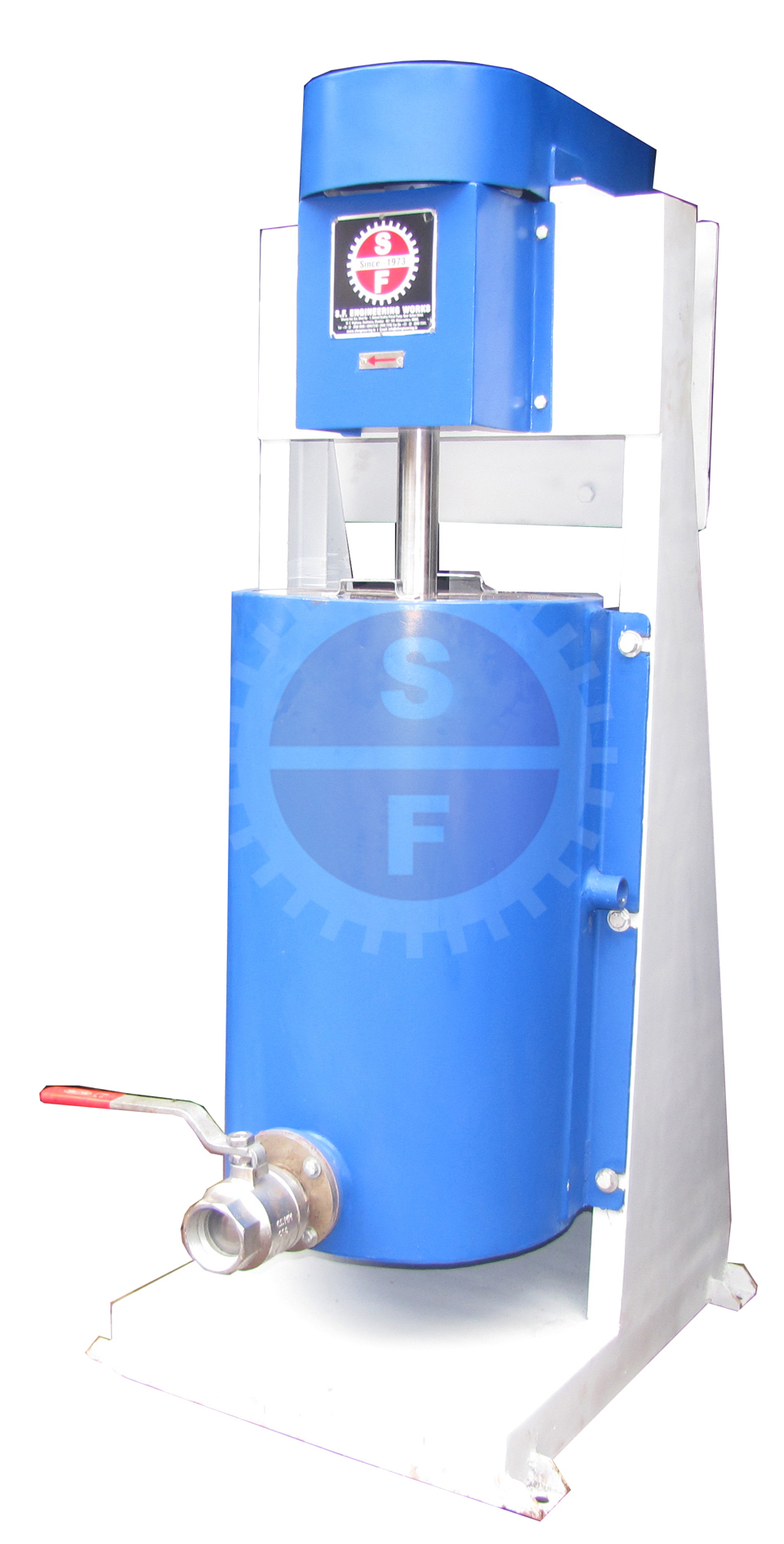

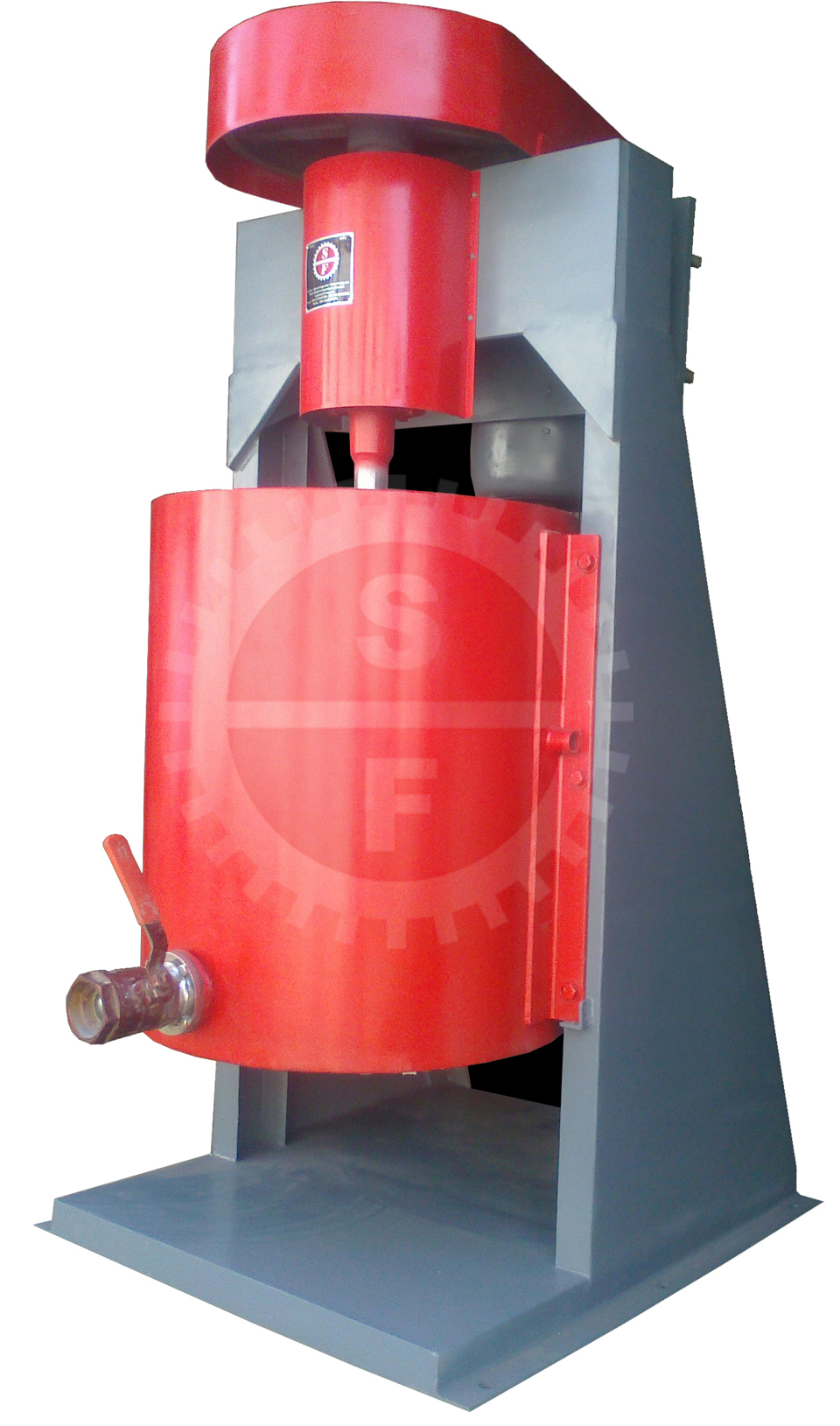

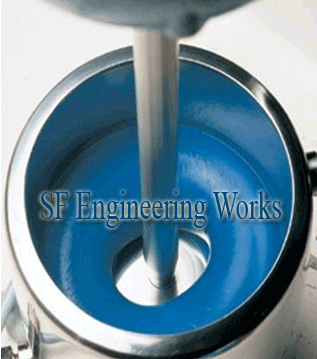

SF BEAD MILL (BATCH TYPE SAND MILL)S.F. BEAD MILL APPLICATION:Solvent And Waterborne Dispersions, Industrial And Architectural Coatings, Automotive Refinishes, Clear Coats, Inks - Liquid, UV, Screen, Paste, Agricultural - Fungicides, Herbicides, Pesticides, Pharmaceutical, Cosmetics, Leather Finishes, Flame Retardants. S.F. BEAD MILL FEATURES & BENEFITS: Finer And Faster Grinding For Inks And Coatings, Single Machine Processing - Premixing, Pre-Grinding, And Milling All In One Machine, Enhanced Quality, Higher Productivity, Simple Operation Small Batch Production, Minimal Solvent Emissions. S.F. BEAD MILL (BATCH TYPE SAND MILL) Having The Grinding Shell Capacity Of --- Liters. This Machine Is Suitable For Grinding Low Medium High Viscosity Material Between 100 CPS And 4000CPS Thixotropics And Product With Highly Pigmented System. The Cabinet Is Totally Enclosed In M.S. Frame Giving Streamline Appearance And Comprises Of The Following.

|

|||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||